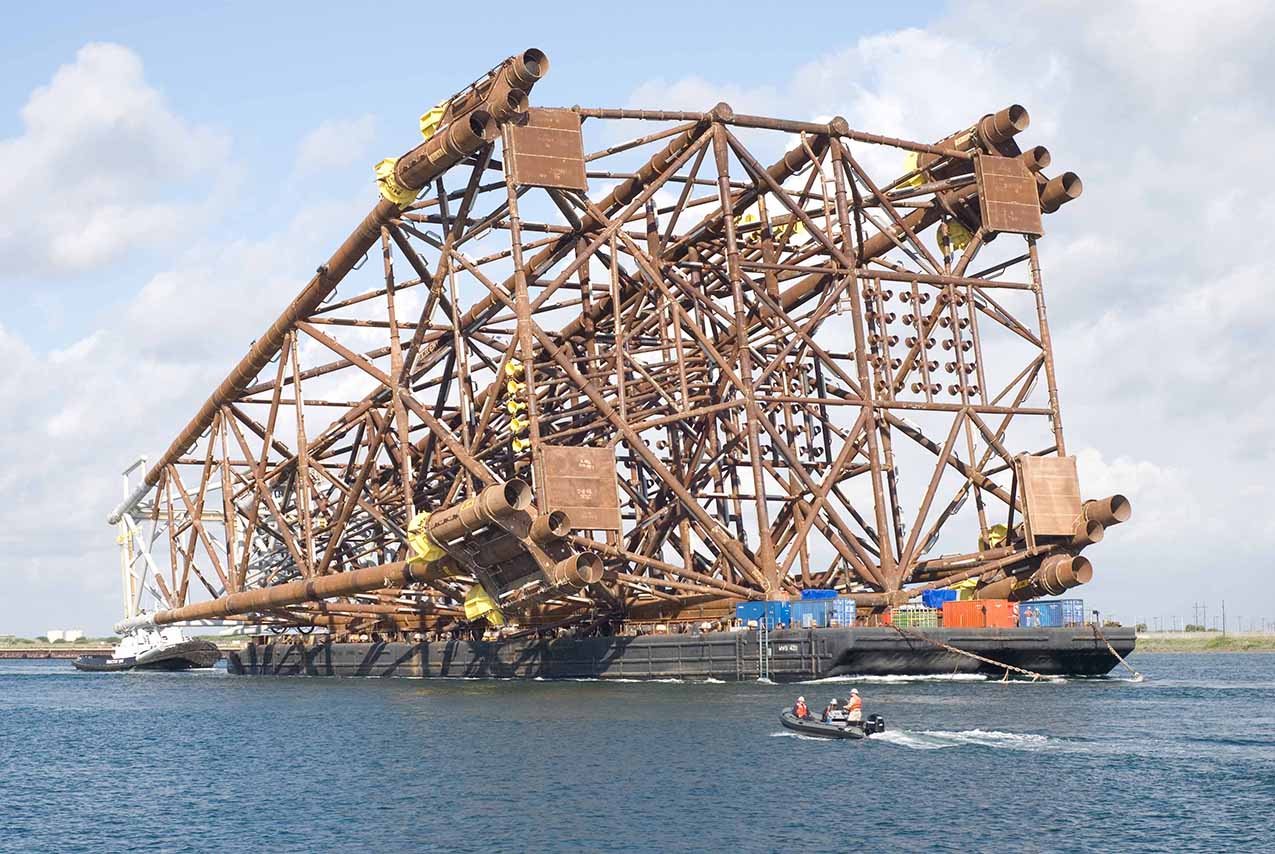

It is not uncommon for a new oil and gas construction project to cost anywhere from $10 million for a basic rig to upwards of $500 million for FPSO projects. Megaprojects with a $25 billion price tag may spend hundreds of millions of dollars on spares alone. At such high stakes, even a small buying or management change can have a big impact on increasing or reducing project costs. Proper preservation and asset management with Cortec® VpCI® Technologies can therefore add up to substantial monetary savings coupled with smoother, safer startup and ongoing operations.

Forecasting of Oil and Gas Spares

According to Sonny Reeves (President of CGSI), who has worked on some of the largest oil and gas development projects in the world, a typical oil and gas construction job will buy an additional 10% (on average) of spares in three different categories:

Construction spares

⦁ Startup/commissioning spares

⦁ Insurance and operating spares

The reason is that some components are expected to fail prior to startup due to mechanical damage, manufacturing flaws, or corrosion. Without backup spares, the discovery of defective equipment at the time of installation or startup could be disastrous, especially in remote areas where delivery lead time is excessive—even if replacement parts were readymade. Forecasting spares by 10%, 12%, or 15% extra is therefore a normal part of risk management.

Reducing Excess Inventory by Spare Preservation

Since corrosion is a major culprit for component failure, rust prevention itself can reduce the number of spares needed. Considering how quickly the cost of spares adds up, a little planning and some good preservation materials could have significant ROI.

Preservation of Construction Spares

Proper preservation must start with primary equipment to ensure that high-dollar—often custom—assets such as heat exchangers, fractionation towers, tanks, and modules will survive the transit and storage period without corrosion. Basic preservation materials such as CorroLogic® Fogging Fluid VpCI®-339 for internal void space preservation, VpCI®-649 for hydrotesting and layup, and MilCorr® VpCI® Shrink Film for external protection are relatively simple to apply and go a long way toward preserving assets in like-new condition so that fewer backups are needed at installation and commissioning.

Preservation of Startup Spares

Startup spares should be preserved along similar lines. Hydrotesting valves, pumps, and vessels with a good dose of VpCI®-649 will help protect against the residual moisture that inherently gets trapped inside during hydrostatic testing. Fogging of voids with Vapor phase Corrosion Inhibitors is also beneficial because the protective vapors form a molecular corrosion inhibiting layer on metal surfaces until the enclosure is opened. VpCI® Films and Bags with UV resistance serve multiple functions by trapping these vapors inside a space, creating a durable barrier to wind and rain, and actively inhibiting corrosion through their own embedded rust preventative chemistry. Protective coatings such as VpCI®-391 are great for temporary protection on exposed metal surfaces such as flange faces.

Preservation of Insurance and Operating Spares

Once the facility moves from startup to full operation, the plant will continue to require backups or “operational spares” to ensure continued uptime. As in other stages, good asset management and preservation of operational spares are critical to keeping parts corrosion free and ready to install on short notice. It can also be good evidence of a proactive safety management plan. In either case, Cortec® VpCI® fogging fluids, films, and coatings again provide an excellent path to preservation.

Optimizing Project Planning and Engineering

Preserving spares at all three stages and documenting the process is a growing trend in asset management with promising results. As Sonny Reeves pointed out in regard to CGSI’s own digital data preservation tool, “It is critical to not only take care of the assets throughout their life, but to be able to provide detailed proof of care to stakeholders.”

This “proof of care” gives project owners a greater chance of reselling or transferring the spares to the next stage of the project rather than scrapping excess inventory and writing it off as a loss. It offers peace of mind and facilitates smooth operations. It can also mean significant savings up front by reducing the number of spares needed.

If these benefits seem more attractive to you than the costs of forecasting excess spare inventory, contact Cortec® for trusted go-to corrosion solutions used in oil and gas projects around the world.

Keywords: overbuying of spares, oil and gas industry, oil and gas spare parts, cost of corrosion oil and gas, forecasting oil and gas spares, spare parts calculation formula, reducing excess inventory, Cortec, metal preservation, rust prevention